Wood Joining at CabinetDoorMart

Posted by Admin on Feb 2nd 2022

When woodworking, carpenters often need to secure two or more pieces of wood together. This is known as wood joinery. There are countless techniques for joining pieces of wood together for countless purposes. From tables and chairs to decorative sculptures, the application of these various techniques is widely varied.

At CabinetDoorMart, our products showcase several different techniques that were used to create their superior quality. In this blog, we are going to take a look at how these techniques work and what they are used to create.

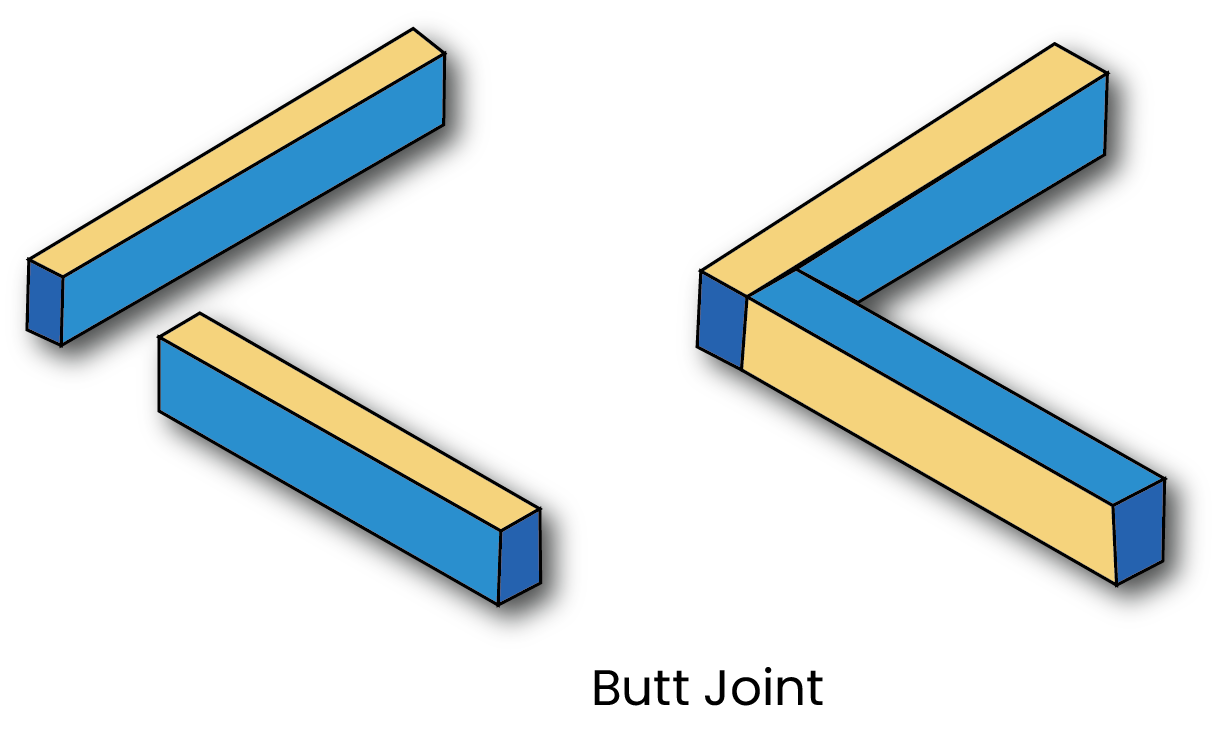

Cope-and-Stick Joint

Cope-and-stick joints, also known as butt joints, are a common way to build both cabinet doors and drawer fronts. In this method, two pieces of wood are joined together at a 90-degree angle. This means that the rails, or the horizontal pieces, fit between the stiles, or the vertical pieces. A Shaker cabinet door is the icon example of this style of construction.

When building a cabinet door or drawer front, a basic cope-and-stick joint is not typically used. Instead, tongues and grooves are cut so that the panel, stiles, and rails can all be fitted together and secured. This provides a stronger bond than a basic cope-and-stick.

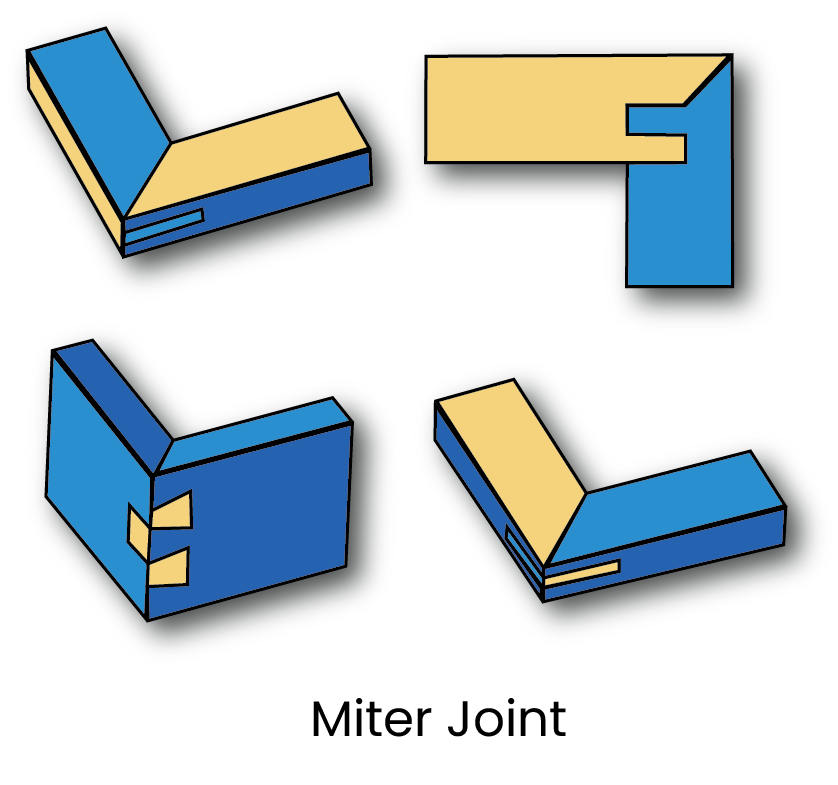

Miter Joints

Another common construction method for cabinet doors and drawer fronts is the mitered joint. For this construction, the stiles and the rails will be the same size, but they will meet to form a 45-degree angle. This is the preferred technique for construction doors and drawer fronts that hide their end grain. This also means that this construction is perfect for a stain finish, as it will highlight both the beauty of the material and craftsmanship.

Slab Syle

While slab style is not a joint type, it has been used in tandem with the more traditional mitered or cope-and-stick joints. Slab-style doors and drawers will not have a frame or panel but they can be combined with any door style for a more affordable option than their 5-pieces counterparts. With solid wood slab doors, larger sizes will require back battens in order to prevent warping or twisting.

Our slab-style cabinet doors and drawer fronts are also available in thermofoil. Thermofoil is a vinyl laminate that is heated and pressurized onto an MDF core. Large thermofoil doors do not need battens, because MDF does not warp or twist at larger sizes like solid wood.

Dowelled Joint

We offer drawer boxes that are constructed using a dowelled joint. This means that corresponding holes are drilled into the sides of the box allowing for dowels to be inserted. These are then fit together and glued for a secure hold.

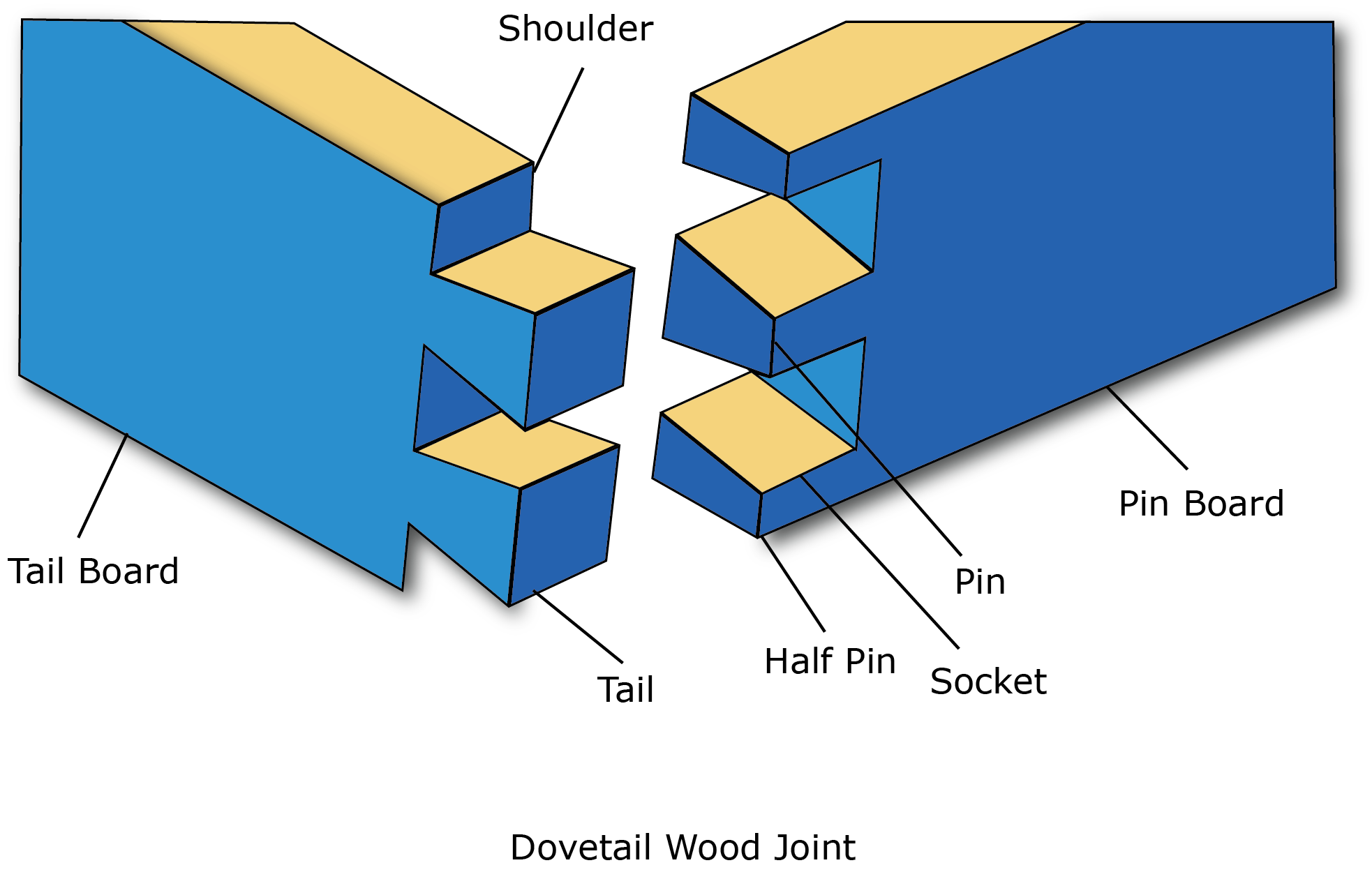

Dovetail Joint

We are also proud to offer drawer boxes constructed using a dovetail joint. A dovetail is a very strong joint that is reminiscent of a box and finger joint. However, a dovetail joint has pins that are wider at the end making the bond stronger.

Our drawer boxes employ a technique called a half-blind dovetail. It is called this because you can only see the pins from the sides of the box, not the front and back. This way, you see the beauty of the grain pattern uninterrupted while at the same time enjoying the strength of the dovetail.

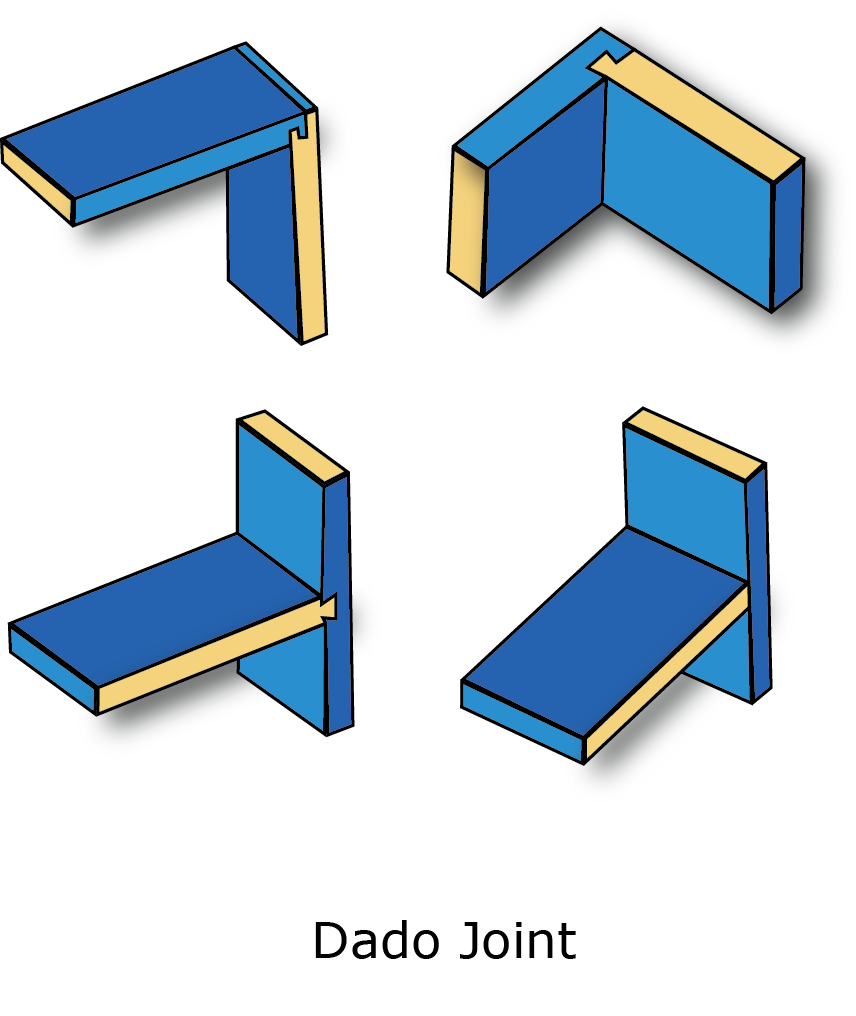

Dado Joints and Cabinet Boxes

A dado joint construction is both practical and strong, plus it makes assembling our RTA cabinets a breeze. In a dado joint construction, one piece will receive the dado cut, as known as the channel. Then another piece of material will be cut and measured to securely slide into the channel and glued. The benefit of this style of construction is that it allows our boxes to be homeowner and DIYer-friendly, without sacrificing strength or quality.

Finishing Up

Woodworking projects would not be possible if it were not for all the creative ways that artisans have developed to join two pieces of wood together. Many joining techniques were designed with specific circumstances in mind, and because there's a fit for every situation you won't ever find yourself without the right tools or materials.

If you are ready to start ordering or if you need assistance, please feel free to call us at 1-844-326-6680 or email info@cabinetdoormart.com. Our team is here to help with everything from measuring to ordering.